OTTO-PRICKEN - machines, engineering, experience & solutions

TRADITIONAL

Founded in 1995, we are active in the fields of metal industry, textile machine construction, construction and production for special machine construction, laboratory equipment and spare parts production for Vald. Henriksen machines.

Since many years we are active with textile machines.

From the laboratory to the production machine, experienced engineers and technicians are at work and, in addition to innovations, also offer solutions that will satisfy you as a customer

Flexibility in production, fast throughput times and high processing skills make us a reliable partner for the worldwide market. Our modern machines for the production of textile machines and spare parts guarantees the highest quality, exact processes and timely deliveries.

The experience in textile machine construction lays the foundation for a successful cooperation.

MANFACTURE AND GUARANTEE

All machines are manufactured in Germany and are subject to test-runbefore they are shipped.

In order to guarantee our high process quality, we subject all products, machines and processes to constant quality controls. These are carried out before, during and after the completion of each project and are carried out both visually and via inline quality assurance systems.

The focus is on the satisfaction of our customers. The zero-defect goal is the basis of what we do. That is why we align our processes with the requirements and expectations of our customers.

By investing in the latest technologies and machines, we continuously improve our process stability and production times. This includes inline camera monitoring, 2D-controlled CNC measuring machines and material testing machines.

With the help of a coupling of the results of our measuring and testing machines in our CAQ system, our specialized employees also control an efficient, precise and at the same time capable and stable production of the components.

OUR TEAM – OUR PROFIT

Together with our employees we pursue a common target! To satisfy you!

The employees of Otto-Pricken Textilmaschinen GmbH & Co.KG are well trained for your needs and represent the most important value in our company.

Let a strong team convince you!

Our team consists of experienced engineers, technicians and specialists who are happy to support and advise you at any time.

QUALITY and ENVIROMENT MANAGEMENT

Achieving the highest quality standards for our products and services is one of our top corporate targets. Our ecological responsibility towards current and future generations are also important for us, especially when it comes to use natural resources.

QUALITY and ENVIROMENT MANAGEMENT

Achieving the highest quality standards for our products and services is one of our top corporate targets. Our ecological responsibility towards current and future generations are also important for us, especially when it comes to use natural resources.

we take responsibility - dyeing clean is the future!

All machines are manufactured in Germany and are subject to test-run before they are shipped.

In order to guarantee our high process quality, we subject all products, machines and processes to constant quality controls. These are carried out before, during and after the completion of each project and are carried out both visually and via inline quality assurance systems.

The focus is on the satisfaction of our customers. The zero-defect goal is the basis of what we do. That is why we align our processes with the requirements and expectations of our customers.

By investing in the latest technologies and machines, we continuously improve our process stability and production times. This includes inline camera monitoring, 3D-controlled CNC measuring machines and material testing machines.

With the help of a coupling of the results of our measuring and testing machines in our CAQ system, our specialized employees also control an efficient, precise and at the same time capable and stable production of the components.

The task was to construct an atmospheric Jigger and a high temperature in a way that consumption demand is held as low as possible and achieve high efficiency production at the same time.

read more....

For every machine there comes the time, where upgrading is a real option to improve a machine performance and efficiency in terms of water, energy and chemical consumption, as well as dyeing quality.

Our Jigger upgrade package can be used by all jiggers like Vald. Henriksen, MCS, Küsters and other brands.

A modern drive technology regulates the transport of goods in the Jigger and controls the desired tension and speed of the goods. This technology enables uniform dyeing of light and heavy goods as well as very complicated goods.

The entire dyeing and washing process is programmed and monitored by special Jigger software.

Typical Jigger problems such crease marks, listing, edge-to-edge, are eliminated by a fully PLC monitoring of bath level, temperature, time, speed, dosing and thus guarantee the best reproducibility.

read more....

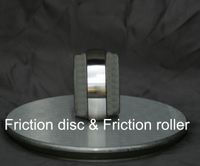

We give you the guarantee for the best and fastest delivery service for:

VH Jigger for VH 800/1000 & 1200.

Our warehouse has a well-organized logistics system and within 24 hours of placing an order, the parts are ready for delivery. A long machine standstill is prevented.

All parts are manufactured in our factory and our quality management checks the quality of the spare parts with the utmost care.

We guarantee the best quality and the best price!

Customers all over the world put their trust in us since very long time.

read more...

AUTOMATION and JIGGER DPC (Drive+Process+Controls)

JIGGER DRIVE DPC:

Green drive and process technology:

Energy efficiency - the model for Jigger

- High efficiency, economy and security

- Integrated measurement and control system

- Individual engineering and process optimization

- Interfaces for central systems

- Project support, training, after-sale and remote service.

Automated and digitalized Jigger dye house: